|

| Zoom |

The DGM FS-1 is a new endoscope reprocessor made by people for people. Our main point is safety for patients, staff and endoscopes.

As the use of endoscopes increases, so does the risk of infections linked to endoscope reprocessing. This is indeed an area where “zero tolerance” towards cross-contamination must be maintained. By the design and development of our new automated Endoscope reprocessor we minimize risk contamination.

Main features:

Main features:

| Applicable scopes | Flexible |

| Capacity | 1 scope per basin |

| Tank capacity | Detergent 1 L, Disinfectant 15 L, Alcohol 1 L |

| Visual Leakage Test | Bubble detection during immersion |

| Washing (detergent) method | |

| Exterior surfaces | Multi-channel jetting system rotated in 3600 arc |

| Channels interiors | Fluid flushing cleaning |

| Disinfection method | |

| Exterior surfaces | Disinfectant solution immersion |

| Channels interiors | Disinfectant solution flushing and filling |

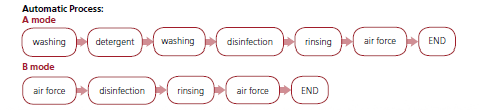

| Working process | |

| Washing time | 0 ~ 10 min |

| Disinfection time | 0 ~ 60 min |

| Alcohol Flushing Time | 5 sec |

| Temperature setting | 150C ~ 500C |

| Dimensions | 550(W) * 585(D) * 950(H) mm |

| Weight | 75 kg |

| Electrical requiremens | 220/230/240 V~; 50/60 Hz |